ZEXI Hair Dryer Engineering Structure Aligned with UL 859 Safety Framework

Dec.19.2025

Independent Technical Review Demonstrates Readiness for North American Compliance

Shenzhen, China | Official Statement by ZEXI

ZEXI has completed an internal engineering validation process supported by a third-party constructional safety review for one of its household hair dryer platforms. The evaluation focuses on the product’s internal structure, safety architecture, and component integration, benchmarked against the requirements of ANSI/UL 859 and the corresponding CSA C22.2 No.36 standard applied in the North American market.

The outcome of this process is documented through a Constructional Data Report (CDR) issued by an accredited testing organization, confirming that the evaluated structure follows the fundamental safety principles required for regulated personal grooming appliances.

Engineering-Focused Review of Hair Dryer Construction

Unlike performance-oriented testing, the constructional review conducted for this hair dryer platform concentrates on how safety is built into the product structure itself. The assessment includes a systematic examination of:

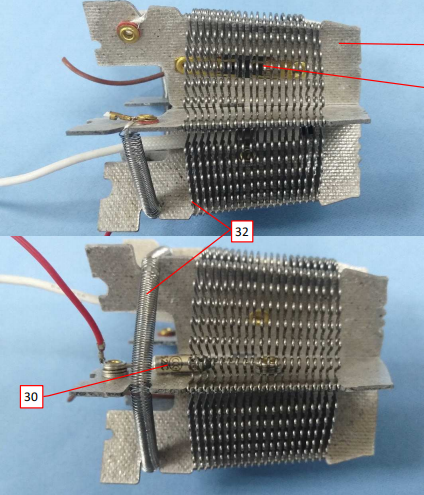

Heating assembly configuration and insulation control

Motor integration and airflow path stability

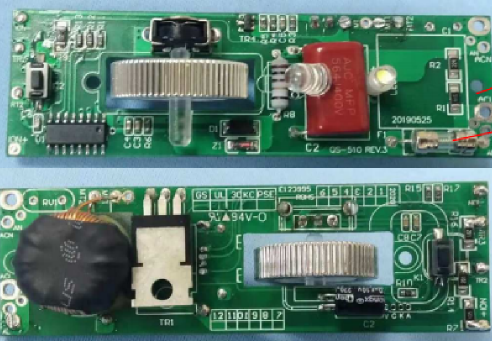

Electronic control board positioning and separation from heat sources

Internal wiring routing, fixation, and strain-relief design

Electrical protection elements and thermal safeguard layout

Integration of an ALCI safety plug for household bathroom environments

This structure-oriented approach aligns with UL 859 expectations for long-term safety, durability, and manufacturing consistency.

Structural Safety Principles Embedded in the Design

From an engineering standpoint, the reviewed hair dryer platform reflects multiple safety principles commonly required for North American compliance, including:

Electrical isolation through double-insulation construction, reducing exposure to live parts

Thermal management architecture, combining thermostats and thermal cutoffs to control abnormal temperature rise

Controlled heating element layout, ensuring safe resistance values and compliant spacing

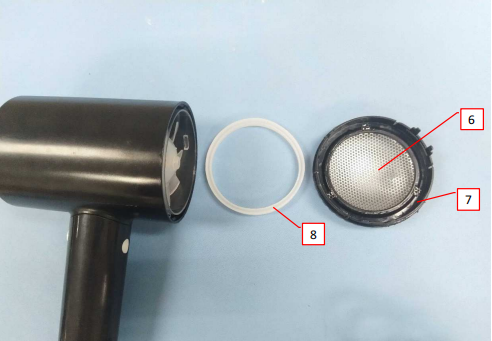

Protective airflow and outlet structures, minimizing the risk of contact with internal heating components

ALCI-based leakage protection, addressing high-risk wet-area usage scenarios

These elements are evaluated collectively as part of the constructional safety framework rather than as isolated features.

|

|

|

Component Strategy Supporting Manufacturing Stability

ZEXI adopts a structure-driven component strategy for this hair dryer platform. Components directly related to electrical and thermal safety are specified based on their suitability for certified appliance applications. Where non-listed parts are used, their placement, function, and interaction with surrounding components are reviewed under the provisions allowed by applicable standards.

This methodology supports stable mass production, simplifies quality control procedures, and ensures consistency between evaluated samples and ongoing manufacturing output.

OEM / ODM Platform for Brand and Private Label Programs

The evaluated hair dryer structure is designed as a flexible OEM / ODM platform, capable of supporting multiple configurations, cosmetic variations, and brand adaptations while maintaining a consistent safety architecture.

For brand owners and distributors targeting North America, this platform-oriented compliance approach helps reduce development time, minimize certification risk, and streamline product introduction across different channels.

ZEXI’s Engineering Commitment to Regulatory Alignment

As a manufacturing-oriented company, ZEXI emphasizes engineering discipline, structural integrity, and regulatory alignment throughout product development. Integrating third-party constructional review into the design phase allows potential compliance issues to be identified and addressed early, supporting long-term market access rather than short-term certification.

ZEXI continues to refine its internal engineering processes in line with international safety frameworks, providing partners with technically robust and compliance-ready hair dryer solutions.

About Constructional Data Review (CDR)

A Constructional Data Report (CDR) is a technical document generated by an accredited testing organization to evaluate whether a product’s internal construction meets the structural safety expectations of applicable standards. It is primarily used for engineering verification, certification assessment, and manufacturing surveillance, and is not intended for consumer-facing claims.